Three

years after announcing its breakthrough in converting MSW to ethanol, Fulcrum

BioEnergy appears to have secured all the funding necessary for its first MSW

to low-carbon fuels plant in Storey County, located 20 miles east of Reno, Nev.

The

Pleasanton, Calif.-based company landed a $105 million loan guarantee by the

U.S. Department of Agriculture in August. Fulcrum originally filed a

registration for an initial public offering with the Securities and Exchange

Commission in September 2011 but rescinded its filing later.

|

| Courtesy: Fulcrum BioEnergy |

“The

current IPO market environment remains challenging, especially for development

stage companies like Fulcrum,” President and CEO James Macias said. “Because of

this we have secured commitments from alternative capital resources to advance

our MSW to renewable fuel program and we have withdrawn our registration

statement.”

Fulcrum

also closed an equity investment agreement with Waste Management in November

2011 that could provide up to $70 million for the Sierra BioFuels plant. The

proposed plant is expected to produce close to 10 million gallons of ethanol

each year. The company secured its feedstock and entered an offtake agreement

for the plant in 2009. In addition to ethanol, the Sierra BioFuels plant will

produce its own renewable energy to run the plant.

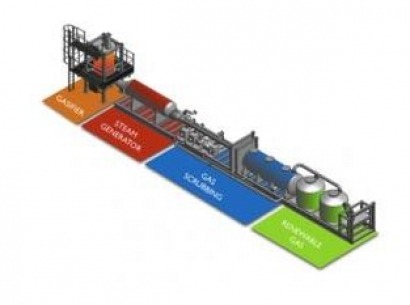

Fulcrum

uses a two-step process to convert post-recycled MSW into ethanol. An InEnTec

downdraft partial-oxidation gasifier is used to convert the sorted MSW to a

syngas. The syngas then runs through a catalyst in Fulcrum’s proprietary

alcohol synthesis process which it developed with Nipawin and the Saskatchewan

Research Council before the ethanol is finally separated and purified.

The

basis of Fulcrum’s business strategy is to secure zero-cost feedstock

agreements around the country, thus giving it a competitive advantage over

those who use corn or other forms of biomass. While Fulcrum has only just

started construction on its Sierra BioFuels plant in Nevada, the company

currently has feedstock agreements in 23 other cities across the U.S.

Better BTU: Fulcrum’s turning point was

landing the $105 million loan from the USDA. The government has laid out

significant dollars in an attempt to jumpstart development of biofuel

technologies that utilize non-food feedstocks. While we’d still like to see the industry focus on clearing

one hurdle – clean, economic and efficient gasification – before approaching

the next, we like Fulcrum’s business approach. Still a lot has to happen if the

plant is to be in production by the end of 2013, as the company states. We’ll

be keeping our eyes peeled for news out of Nevada.

Recommended Reading:

Fulcrum Secures $175M for

Waste-to-Fuel Gasification Project – Waste

Management World (Dec. 3, 2012)

$105 Million USDA Loan

Guarantee for Waste-to-Biofuel Facility – Waste

Management World (Aug. 7, 2012)