After nine months of negotiation with the city of Ottawa, it

looks like Plasco Energy Group is “very close” to signing its first commercial

deal.

|

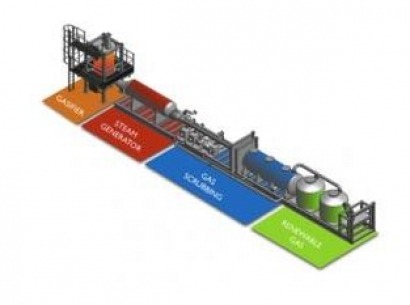

| Courtesy: Plasco Energy Group |

The local company had reached an initial agreement in

December to build and operate a facility that would convert 300 tons of

post-recycled MSW per day using a plasma gasification system. Plasma gasification heats the waste to temperatures

above 4,000 degrees Fahrenheit to convert it to a syngas that can be used to

generate electricity or steam.

The city has agreed to a 20-year deal that that would cost

$9.1 million annually to send 300 tons of trash per day to the facility. While

this is still a hefty price tag for residents, it is actually less than they

are paying now to dump waste in the nearby Trail Road landfill. The city

currently pays a $96 tip fee to landfill owners. The $9.1 million the city will

pay annually to Plasco includes an $83.25 tip fee once the facility is up and running.

Perhaps more importantly, the deal with Plasco will extend

the life of the Trail Road landfill. Currently on pace to reach maximum

capacity in 2042, the Plasco deal means the city would be able to continue

dumping trash until 2070. The city estimates the cost of a new landfill to be

close to $250 million.

A by-product of plasma gasification is slag, a non-toxic

solid that looks like a shiny black rock. Plasco hopes to sell that slag as an

aggregate for concrete or asphalt. Under the current deal with Ottawa, Plasco’s

Trail Road facility would produce roughly 11,600 tons of slag each year. The

city will receive the material at no cost and is hoping to use it to build a

ramp to the landfill and facility. Slag is still untested as an aggregate for

roadways since the current demonstration model does not run on a consistent

enough basis to create large enough quantities of slag.

A by-product of plasma gasification is slag, a non-toxic

solid that looks like a shiny black rock. Plasco hopes to sell that slag as an

aggregate for concrete or asphalt. Under the current deal with Ottawa, Plasco’s

Trail Road facility would produce roughly 11,600 tons of slag each year. The

city will receive the material at no cost and is hoping to use it to build a

ramp to the landfill and facility. Slag is still untested as an aggregate for

roadways since the current demonstration model does not run on a consistent

enough basis to create large enough quantities of slag.

City council members have the distinct advantage of already

seeing a commercial-scale demonstration of Plasco’s plasma gasification

technology in its own backyard. The 100 tpd demonstration facility was built at

the Trail Road landfill site in late 2010 and has been running intermittently ever

since. The site passed its environmental screening test and received a

Certificate of Approval (Air & Waste) on Oct. 24, 2011. Although some city

council members have voiced fears that the facility had not been running on a

continuous basis for a full year, the large size of the demonstration facility

should ease concerns of scaling the technology for a larger facility.

Better BTU Take: Plasco

Energy has received an unparalleled amount of financial support from private

investors like George Soros (see our previous blog post Finding

Funding: Plasco’s Biggest Supporter) and we’re glad to see something come

of it. Plasma gasification is viewed as one of the cleanest forms of

gasification but it’s the cost that is going to keep it from becoming a

widespread solution on American soil. This technology can only work where tip

fees are extremely high, as they are in Ottawa. That leaves New York and

California as the best bets for a project in the states.

Interestingly enough, Plasco’s plan to build a facility in

Salinas Valley, California has recently hit the skids. CalRecycle, the agency

charged with overseeing California’s recycling and solid waste reduction

notified Plasco on Aug. 23rd that its process didn’t appear to meet

the state’s definition of gasification, preventing it’s electricity from

receiving coveted ‘renewable energy’ status it needs to sell to utilities. The

block comes almost two years after CalRecycle originally approved Plasco’s

process and reports are that this is a purely political issue. Still, it hurts

Plasco, who has already invested $1 million in the project.

Although there is no link between the Salinas Valley and

Ottawa projects, it is worth noting that Plasco is still ironing out a deal to

sell its energy to Ontario Power Authority. Should this become an issue at any

point, there will be definite parallels between this project and the California

one. Just goes to show you that nothing is certain ‘til the ink is dry and the

facility is built and operating!

Further Reading: